Product Description

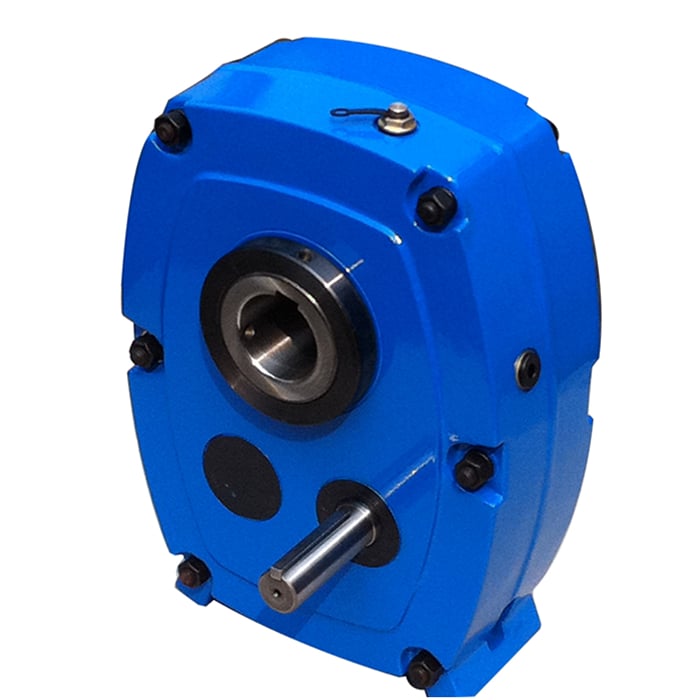

Detailed Images

Detailed Images of Three Types Helical Gearbox Shaft Mounted Reducer

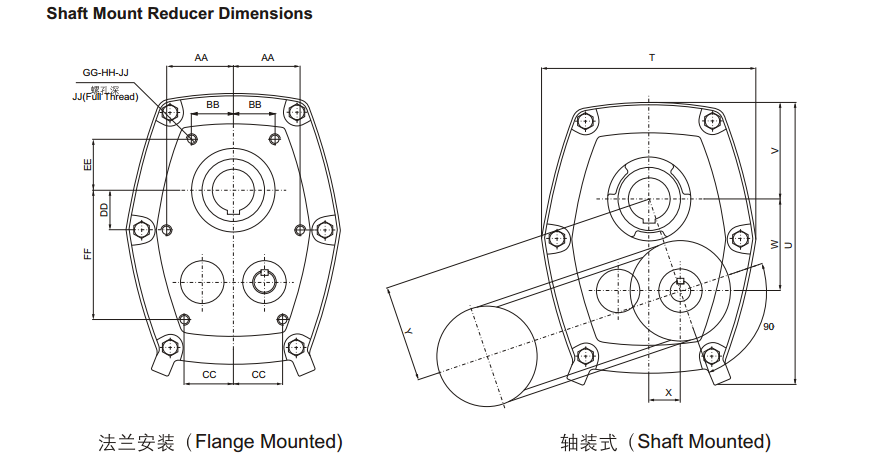

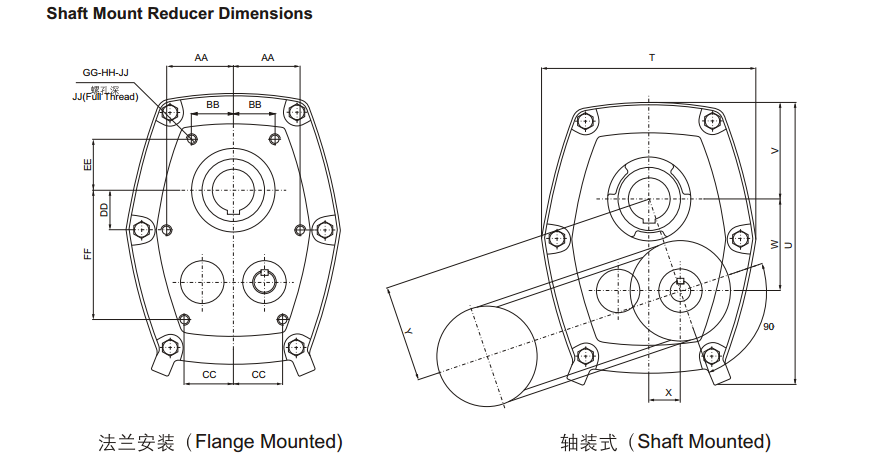

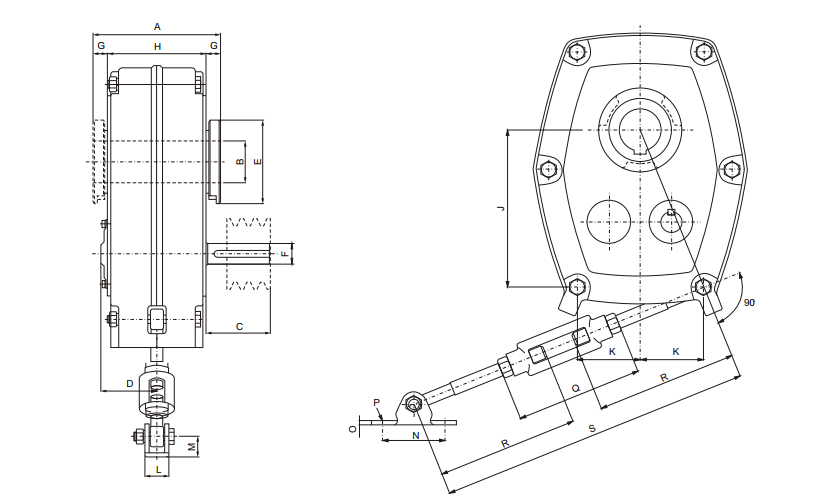

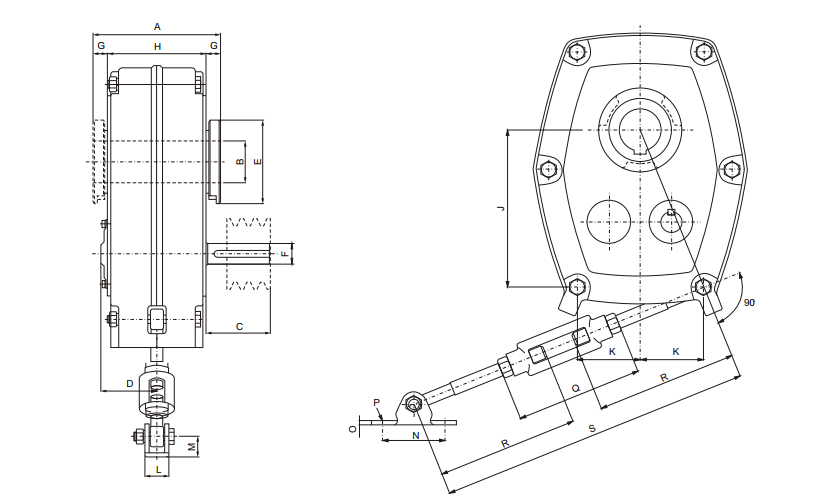

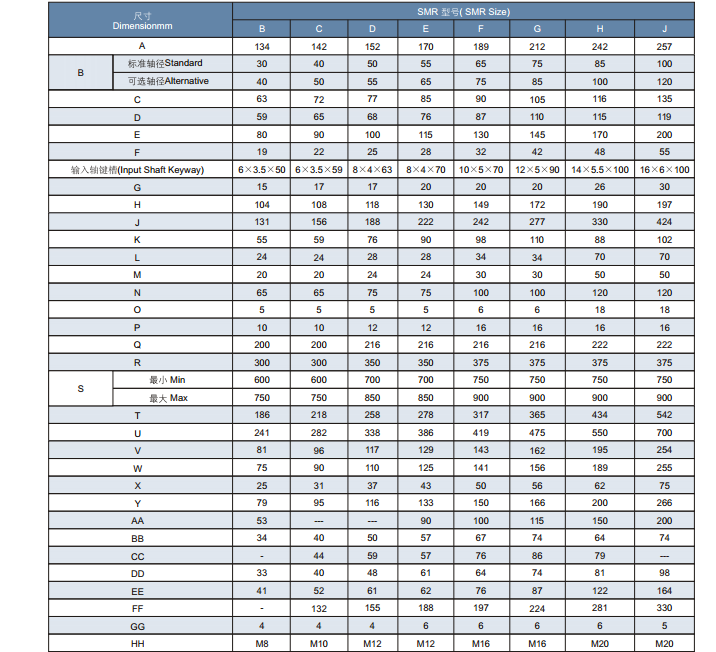

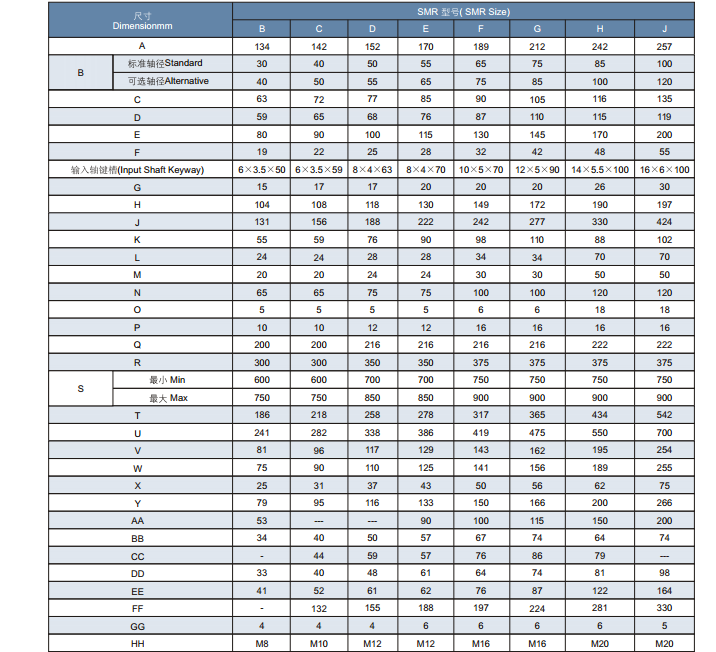

Detailed Dimensions of Helical Gearbox Shaft Mounted Reducer

Product Description

Helical Gearbox Shaft Mounted Reducer

1. Precision High Quality Gearing

Computer designed helical gears, strong alloy materials for high load capacity, ground profile (some intermediate pinions are shaved). CHINAMFG tooth profile, in conformance with ISO 1328-1997, 98% efficiency for per stage, smooth quiet operation with several teeth in mesh.

2. Output Hub

*Standard or alternative output hole diameter for choice as follow.

|

ITEM |

Standard output hole diameter |

Alternative output hole ø |

|

B5 |

ø30 |

ø25/35/40 |

|

B13/20 |

ø30 |

ø25/35/40 |

|

C5 |

ø40 |

ø35/45/50 |

|

C13/20 |

ø40 |

ø35/45/50 |

|

D5 |

ø50 |

ø45/55/60/65 |

|

D13/20 |

ø50 |

ø45/55/60/65 |

|

E5 |

ø55 |

ø50/60/65 |

|

E13/20 |

ø55 |

ø50/60/65 |

|

F5 |

ø65 |

ø60/70/75 |

|

F13/20 |

ø65 |

ø60/70/75 |

|

G5 |

ø75 |

ø70/80/85 |

|

G13/20 |

ø75 |

ø70/80/85 |

|

H5 |

ø85 |

ø80/90/95/100 |

|

H13/20 |

ø85 |

ø80/90/95/100 |

|

J5 |

ø100 |

ø90/95/105/110/15710 |

|

J13/20 |

ø100 |

ø90/95/105/110/15710 |

3. Strong Alloy Steel Shafts

Strong alloy steel, hardened, ground on journals, gear seatings and extensions, for maximum torsional loads. Generous size shaft keys for shock loading and conform to ISO standards.

4, Back Stops

Alternative parts, anti-run back device, are available on all 13:1 and 20:1. Ratio units and do not recommend for 5:1.

5. Torque Arm Assembly

For easy adjustment of the belt.

Packing & Delivery

Packing Images of Worm Gear Reducer Worm Gearbox NMRV 130 150

Inner Packing: PP bag with carton

Outer Packing: Carton boxes or wooden cases

Leadtime: 20-30 days after order confirm

About Us

Formerly known as HangZhou Reducer Factory, CHINAMFG Group was founded in 1976.

Presently, our commitment extends beyond manufacturing as we engage in diligent research and trading endeavors. Our primary focus

centers on power transmission products, constituting the core of our business operations.

Having invested a total of 2 billion Yuan in land spHangZhou an impressive 200,000 square meters, our workforce of 1000 dedicated

employees now produce over 3,500 distinct types of gearboxes each day, serving the global market.

With unwavering commitment to research and development over a span of 45 years, CHINAMFG takes great pride in holding the esteemed distinction of being the largest manufacturer of small and medium-sized speed reducers in Asia.

Our main products range from Worm Gear Reducers, Helical Gear Reducers, Helical Bevel Reducers, Shaft Mounted Reducers to Slewing

drives and more.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery, Marine, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Parallel |

| Gear Shape: | Bevel Gear |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

Maintenance Tips for Prolonging the Life of a Worm Gearbox

Proper maintenance is essential to ensure the longevity and reliable performance of a worm gearbox. Here are some maintenance tips to consider:

- Lubrication: Regularly check and replenish the lubricant in the gearbox. Use the recommended lubricant type and quantity specified by the manufacturer.

- Lubrication Schedule: Follow a lubrication schedule based on the operating conditions and manufacturer recommendations. Regular lubrication prevents friction, reduces wear, and dissipates heat.

- Temperature Monitoring: Keep an eye on the operating temperature of the gearbox. Excessive heat can degrade the lubricant and damage components.

- Cleanliness: Keep the gearbox and surrounding area clean from debris and contaminants. Regularly inspect and clean the gearbox exterior.

- Seal Inspection: Check for any leaks or damage to seals and gaskets. Replace them promptly to prevent lubricant leaks and contamination.

- Alignment: Ensure proper alignment between the worm and worm wheel. Misalignment can lead to increased wear and reduced efficiency.

- Torque Monitoring: Monitor the torque levels during operation. Excessive torque can cause overloading and premature wear.

- Regular Inspections: Periodically inspect all components for signs of wear, damage, or unusual noise. Replace worn or damaged parts promptly.

- Proper Usage: Operate the gearbox within its specified limits, including load, speed, and temperature. Avoid overloading or sudden changes in operating conditions.

- Expert Maintenance: If major maintenance or repairs are needed, consult the manufacturer’s guidelines or seek the assistance of qualified technicians.

By following these maintenance tips and adhering to the manufacturer’s recommendations, you can extend the lifespan of your worm gearbox and ensure its optimal performance over time.

Worm Gearbox vs. Helical Gearbox: A Comparison

Worm gearboxes and helical gearboxes are two popular types of gear systems, each with its own set of advantages and disadvantages. Let’s compare them:

| Aspect | Worm Gearbox | Helical Gearbox |

| Efficiency | Lower efficiency due to sliding friction between the worm and worm wheel. | Higher efficiency due to rolling contact between helical gear teeth. |

| Torque Transmission | Excellent torque transmission and high reduction ratios achievable in a single stage. | Good torque transmission, but may require multiple stages for high reduction ratios. |

| Noise and Vibration | Generally higher noise and vibration levels due to sliding action. | Lower noise and vibration levels due to smoother rolling contact. |

| Backlash | Higher inherent backlash due to the design. | Lower backlash due to meshing of helical teeth. |

| Efficiency at Higher Speeds | Less suitable for high-speed applications due to efficiency loss. | More suitable for high-speed applications due to higher efficiency. |

| Overload Protection | Natural self-locking feature provides some overload protection. | May not have the same level of inherent overload protection. |

| Applications | Commonly used for applications requiring high reduction ratios, such as conveyor systems and heavy-duty machinery. | Widely used in various applications including automotive transmissions, industrial machinery, and more. |

Both worm and helical gearboxes have their place in engineering, and the choice between them depends on the specific requirements of the application. Worm gearboxes are preferred for applications with high reduction ratios, while helical gearboxes are chosen for their higher efficiency and smoother operation.

Preventing Backlash in a Worm Gearbox

Backlash in a worm gearbox can lead to reduced accuracy, positioning errors, and decreased overall efficiency. Here are steps to prevent or minimize backlash:

- High-Quality Components: Use high-quality worm gears and worm wheels with tight manufacturing tolerances. Precision components will help reduce backlash.

- Proper Meshing: Ensure the worm gear and worm wheel are properly aligned and meshed. Improper meshing can lead to increased backlash.

- Preload: Applying a small amount of preload to the worm gear can help reduce backlash. However, excessive preload can increase friction and wear.

- Anti-Backlash Mechanisms: Consider using anti-backlash mechanisms, such as spring-loaded systems or adjustable shims, to compensate for any inherent backlash.

- Lubrication: Proper lubrication can reduce friction and play a role in minimizing backlash. Use a lubricant that provides good film strength and reduces wear.

- Maintenance: Regularly inspect and maintain the gearbox to identify and address any changes in backlash over time.

It’s important to strike a balance between reducing backlash and maintaining smooth operation. Consulting with gearbox experts and following manufacturer guidelines will help you optimize your worm gearbox’s performance while minimizing backlash.

editor by CX 2024-03-27

China Hot selling S-Series Hollow Shaft Mounted Helical Gear – Worm Gear Reducer Gearbox bevel gearbox

Product Description

Product Description

BOQIANG Drive S Series Helical-Worm Geared Motor

Features:

-High efficiency: 75%-80%;

-High technology: the helical gear and a worm gear combined with an integrated transmission to improve the torque and efficiency.

-High precision: the gear is made of high-quality alloy steel forging, carbonitriding and hardening treatment, grinding process to ensure high precision and stable running.

-High interchangeability: highly modular, serial design, strong versatility and interchangeability.

Helical gear and worm gear combination, compact structure, large reduction ratio.

Installation mode: foot installation, hollow shaft installation, flange installation, torque arm installation, small flange installation.

Input mode: motor direct connection, motor belt connection or input shaft, connection flange inpu

Mounting position

Position of the motor thermal box

|

S series worm helical gearbox reducer |

|

|

Product name |

S-series gearbox hollow shaft S77 oil sealed gearbox reducer |

|

Warranty |

1 years |

|

Applicable Industries |

Manufacturing Plant |

|

Weight (KG) |

50KG |

|

Customized support |

OEM |

|

Gearing Arrangement |

worm and helical gear |

|

Output Torque |

1.8-2430N.M |

|

Input Speed |

1440, 2800,960,750 |

|

Output Speed |

0.5 to 200 |

|

Place of Origin |

China |

|

Product name |

S-series gearbox hollow shaft S77 oil sealed gearbox reducer |

|

Application |

Hardened Tooth Surface |

|

Installation |

Horizontal Type |

|

Layout |

Coaxial |

|

Gear Shape |

Helical |

|

Production Capacity |

5000PCS /Month |

|

Type |

Gear Reduction Motor |

|

Color |

Blue,Sliver or Customized |

|

Packing |

Wooden Box |

Photos of the factory area

the factory area

ZHangZhoug Boqiang Transmission Co., Ltd. was established in 2002 and is a high-tech enterprise that integrates design, development, manufacturing, and operation, producing and selling reduction motors and power transmission equipment. The company is located in Oubei Town, HangZhoua County, at the forefront of national reform and opening up, known as the “Little Xihu (West Lake) Dis.” of HangZhou. Close to National Highway 104 and east to HangZhou International Airport and Xihu (West Lake) Dis. International Container Terminal; South to HangZhou Railway Station and Passenger Transport Center; There are also many national tourist attractions such as Yandang Mountain and Xihu (West Lake) Dis. River. With convenient transportation and unique geographical location, it is highly welcomed by domestic and foreign users.

Our company produces 12 series of helical gear reducers for various purposes, including shaft mounted helical gear reducers, helical bevel gear reducers, helical worm gear reducers, spiral bevel gear steering boxes, worm gear reducers, continuously variable transmissions, spiral elevators, and large gearboxes. The power coverage is 0.12-2000kw, with a reduction ratio of 1.25-30000. Various combinations, deformations, and specialized products can meet most industrial requirements. The R, K, F, and S series reducers adopt the modular design principle of unit structure, greatly reducing the types of components and inventory, and greatly shortening the delivery cycle. The components have strong universality and low maintenance costs.

Boqiang has a leading position in China in terms of technology level and product market share. The products are widely used in various fields such as metallurgy, light industry, packaging, medicine, petroleum, chemical industry, lifting and transportation, three-dimensional parking, printing and dyeing, elevators, wind power, etc. Boqiang Company has excellent performance. The transmission technology experts from the headquarters and numerous application engineers and after-sales service technicians from various regional offices provide you with rapid and comprehensive technical consultation and comprehensive services.

Looking back at the past and looking CZPT to the future, Boqiang has always been on the way forward, constantly improving and surpassing itself with high-quality products and comprehensive services, and winning the favor of the market and customers. We are willing to work together with people of insight from all walks of life to create a more brilliant tomorrow.

QUALITY CONTROL

Quality:Insist on Improvement,Strive for CZPT With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of excellence

Quality Philosophy:Quality creates value

Supporting equipment

Packaging And Transportation

FAQ

Q1: I want to buy your products, how can I pay?

A: You can pay via T/T(30%+70%), L/C ,D/P etc.

Q2: How can you guarantee the quality?

A: One year’s warranty against B/L date. If you meet with quality problem, please send us pictures or video to check, we promise to send spare parts or new products to replace. Our guarantee not include inappropriate operation or wrong specification selection.

Q3: How we select models and specifications?

A: You can email us the series code (for example: RC series helical gearbox) as well as requirement details, such as motor power,output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings,it is nice.

Q4: If we don’t find what we want on your website, what should we do?

A: We offer 3 options:

1, You can email us the pictures, drawings or descriptions details. We will try to design your products on the basis of our

standard models.

2, Our R&D department is professional for OEM/ODM products by drawing/samples, you can send us samples, we do customized design for your bulk purchasing.

3, We can develop new products if they have good market. We have already developed many items for special using successful, such as special gearbox for agitator, cement conveyor, shoes machines and so on.

Q5: Can we buy 1 pc of each item for quality testing?

A: Yes, we are glad to accept trial order for quality testing.

Q6: How about your product delivery time?

A: Normally for 20’container, it takes 25-30 workdays for RV series worm gearbox, 35-40 workdays for helical gearmotors.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Gearbox |

|---|---|

| Function: | Clutch, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Customization: |

Available

| Customized Request |

|---|

Can a Worm Gearbox Be Used in Heavy-Duty Machinery?

Yes, a worm gearbox can be used in heavy-duty machinery and is often chosen for such applications due to its inherent characteristics and advantages:

- High Torque Transmission: Worm gearboxes are known for their ability to transmit high torque loads, making them suitable for heavy-duty machinery that requires significant power transmission.

- Load Distribution: The design of worm gears provides robust load distribution and excellent contact between the worm and worm wheel teeth. This enhances their load-carrying capacity, making them capable of handling heavy loads without premature wear or failure.

- Compact Design: Worm gearboxes are compact and offer high reduction ratios in a single stage. This allows for the reduction of high input speeds to lower output speeds, often required in heavy-duty machinery.

- Overload Protection: Worm gears have a natural self-locking feature, which means the gear cannot be easily back-driven by external forces. This feature provides inherent overload protection, preventing damage to the gearbox and machinery in cases of sudden load spikes.

- Smooth Operation: Worm gearboxes offer smooth and steady operation, which is crucial for heavy-duty machinery where precision and controlled movement are essential.

However, when considering the use of a worm gearbox in heavy-duty applications, it’s important to ensure proper engineering and sizing. The design should account for factors such as load, speed, duty cycle, lubrication, and temperature to ensure optimal performance and longevity.

Overall, worm gearboxes are well-suited for heavy-duty machinery across various industries, including mining, construction, manufacturing, and more.

Diagnosing and Fixing Oil Leakage in a Worm Gearbox

Oil leakage in a worm gearbox can lead to reduced lubrication, increased friction, and potential damage to the gearbox components. Here’s a step-by-step process to diagnose and fix oil leakage:

- Inspect the Gearbox: Perform a visual inspection of the gearbox to identify the source of the leakage. Check for oil stains, wet spots, or oil pooling around the gearbox.

- Check Seals and Gaskets: Inspect the seals, gaskets, and O-rings for any signs of wear, cracks, or damage. These components are common points of leakage.

- Tighten Bolts and Fasteners: Ensure that all bolts, screws, and fasteners are properly tightened. Loose fasteners can create gaps that allow oil to escape.

- Replace Damaged Seals: If you find damaged seals or gaskets, replace them with new ones. Use seals that are compatible with the operating conditions and lubricant.

- Check Breather Vent: A clogged or malfunctioning breather vent can cause pressure buildup inside the gearbox, leading to leakage. Clean or replace the breather vent if necessary.

- Examine Shaft Seals: Check the shaft seals for wear or damage. If they’re worn out, replace them with seals of the appropriate size and material.

- Use Proper Lubricant: Ensure that you’re using the correct lubricant recommended for the gearbox. Using the wrong type of lubricant can cause leaks.

- Apply Sealants: In some cases, applying a suitable sealant to the joints and connections can help prevent leaks. Follow the manufacturer’s instructions for proper application.

- Monitor Leakage: After addressing the issues, monitor the gearbox for any signs of continued leakage. If leakage persists, further investigation may be required.

- Regular Maintenance: Implement a regular maintenance schedule that includes checking seals, gaskets, and other potential leakage points. Timely maintenance can prevent future leakage issues.

If you’re unsure about diagnosing or fixing oil leakage in a worm gearbox, consider consulting with a professional or gearbox manufacturer to ensure proper resolution.

Lubrication Requirements for a Worm Gearbox

Lubrication is crucial for maintaining the performance and longevity of a worm gearbox. Here are the key considerations for lubricating a worm gearbox:

- Type of Lubricant: Use a high-quality, high-viscosity lubricant specifically designed for worm gearboxes. Worm gearboxes require lubricants with additives that provide proper lubrication and prevent wear.

- Lubrication Interval: Follow the manufacturer’s recommendations for lubrication intervals. Regularly check the gearbox’s temperature and oil condition to determine the optimal frequency of lubrication.

- Oil Level: Maintain the proper oil level to ensure effective lubrication. Too little oil can lead to insufficient lubrication, while too much oil can cause overheating and foaming.

- Lubrication Points: Identify all the lubrication points on the gearbox, including the worm and wheel gear surfaces. Apply the lubricant evenly to ensure complete coverage.

- Temperature: Consider the operating temperature of the gearbox. Some lubricants have temperature limits, and extreme temperatures can affect lubricant viscosity and performance.

- Cleanliness: Keep the gearbox and the surrounding area clean to prevent contaminants from entering the lubricant. Use proper filtration and seals to maintain a clean environment.

- Monitoring: Regularly monitor the gearbox’s temperature, noise level, and vibration to detect any signs of inadequate lubrication or other issues.

Proper lubrication will reduce friction, wear, and heat generation, ensuring smooth and efficient operation of the worm gearbox. Always refer to the manufacturer’s guidelines for lubrication specifications and intervals.

editor by CX 2023-09-08

in Luanda Angola sales price shop near me near me shop factory supplier Smr Shaft Mounted Gear Reducer Shaft Mounted Speed Reducer Gearbox manufacturer best Cost Custom Cheap wholesaler

focus in power transmission goods, CATV merchandise, mechanical seal, hydraulic and Pheumatic, and marketing goods. we source chromed bar and tubes for hydualic and pheumatic cylinders. We will supply best solutions and large quality goods with all sincerity.

SMR EPT Specification

1 Output Hub

StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd or alternative hubs with metric bores are available to suit global stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd shaft diameters.

2 EPT Large EPT Gearing

Personal computer Developed Helical Gears, EPT Alloy EPTs for Large Load Capability, Scenario Carburized for EPT life, Floor Profile(some intermediate pinions are shaved) EPT tooth Profile, In Conformance with ISO 1328-1997, ninety eight% Efficiency for For each Stage, Smooth Silent Procedure with A number of Teeth in Mesh.

three MaXiHu (West Lake) Dis.mum Capability EPT Design and style

Shut Grain Solid Iron Development, Superb Vibration Dampening amp Shock Resistance Attributes, EPT Bored and Dowelled to Make certain Exact In-Line Assembly.

four EPT Alloy Metal Shafts

EPT Alloy Steel, Hardened, Floor on Journals, Gear Seatings and Extensions, for

MaXiHu (West Lake) Dis.mum Load and MaXiHu (West Lake) Dis.mum Torsional Hundreds. Generous Dimension Shaft

Keys for Shock Loading and Conform to ISO StXiHu (West Lake) Dis.Hu (West Lake) Dis.rds.

5 Additional Scenario Lugs Besides H and J Gear Circumstance

Removes the Need to have for Essential Tightening of Torque Arm Bolts. Controls Position of

StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd Torque Arm Mounting inside of EPTmmended boundaries.

six BackStops

Alternative Parts, Antirun Back again Device, AreAvailable on all 13:1 and twenty:one Ratio Units and do not suggest for five:1 Models.

seven EPTs and Oilseals

EPTs are Sufficiently Proportioned and Conform to ISO Dimension Prepare, Readily

Obtainable EPTWide. Oilseals are EPT Lipped XiHu (West Lake) Dis.Hu (West Lake) Dis.ter Spring Variety, Ensuring Successful Oil Sealing.

eight EPTised Stop Caps

Self Sealing Intermediate EPT Plates, to StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd ISO EPT Dimensions.

nine Torque Arm Assembly

For EPT Adjustment of the Belt.

Dimensions : SMR B C D E F G H

RATIO : 5:one 13:1 twenty:one

Make contact with Me

Welcome to make contact with William for a lot more specifics!

| Model | B13/B20 | C13/C20 | D13/D20 | E13/C20 | F13/E20 | G13/F20 | H13/G20 | J13/J20 |

| Output(RPM) | 10-one hundred fifteen | 10-a hundred and ten | ten-110 | ten-one hundred and five | ten-one zero five | 10-100 | ten-100 | 10-a hundred |

| EPT Rating(KW) | .29-three.11 | .forty nine-4.62 | .82-seven.81 | 1.25-eleven.fifty five | 1.97-17.01 | three.eleven-27.09 | four.nine-40.seven | 7.eight-60.five |

| Permissible torque(Nm) | 277 | 468 | 783 | 1194 | 1881 | 2970 | 4680 | 7449 |

| Model | B5 | C5 | D5 | E5 | F5 | G5 | H5 | J5 |

| Output(RPM) | 100-400 | one hundred-400 | a hundred-400 | 100-four hundred | 100-four hundred | a hundred-400 | a hundred-four hundred | a hundred-400 |

| EPT Score(KW) | two.68-7.fourteen | four.2-nine.sixty six | six.62-fifteen.65 | ten.29-24.57 | fifteen.twelve-35.91 | 25.two-59.nine | 36.2-81.9 | 62.two-134.two |

| Permissible torque(Nm) | 256 | 401 | 632 | 983 | 1444 | 2407 | 3457 | 5940 |

| Dimension(mm) | SMR Measurement | |||||||

| SMR-B | SMR-C | SMR-D | SMR-E | SMR-F | SMR-G | SMR-H | SMR-J | |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd size of shaft | 30 | 40 | fifty | 55 | sixty five | 75 | eighty five | 100 |

| Alternative size of shaft | 40 | 50 | 55 | sixty five | seventy five | eighty five | one hundred | 120 |

| Input shaft keyway | 6×3.5×50 | 6×3.5×59 | 8x4x63 | 8x4x70 | 10x5x70 | 12x5x90 | 14×5.5×100 | 16x6x100 |

Firm Profile

l The biggest manufacturer and exporter of worm EPT EPTs in Asia.

l EstabEPTd in 1976, we transformed from a EPT owned manufacturing facility to non-public one in 1996. HangEPT EPT-DEUTSCH EPT EPT Equipment CO.,LTD is our new title considering that 2001.

l We are the 1st producer of EPTs and EPTes in EPT who was provided export license because yr 1993.

l quotFixedstar quot brand EPTes and EPTs are the first operator of CHINA Leading Manufacturer and Most Renowned EPT Mark for EPTs.

Initial to obtain ISO9001 and CE Certification among all manufacturers of EPTes in EPT.

As a skilled producer of worm EPT and worm EPT EPTs in EPT, we mostly generate reduction EPT,EPT situation worm EPTes,arc EPT cylindrical worm EPTes, worm EPT EPTs, in line helical EPTes, and cyclo EPT EPTs, and so on. These products attribute rational construction, steady efficiency, and trustworthy top quality, and so on. They are extensively utilized in EPT, mining, metallurgy, building content, chemical, food, printing, ceramic, paper-creating, tobacco, and other EPT.

We have 600 workers in our factory, which addresses 70,000 square meters in HangEPT. We have been generating two,500 models of EPTs each day because 2012. We are proudly exporting 70% of our items to more than forty nations around the world all more than the phrase. Our customers arrive from EPT, Germany, United states of america, Canada, Spain, British isles, MeXiHu (West Lake) Dis.co, Brazil, Argentina, Turkey, Singapore and other major EPT nations around the world in the globe. 30% of them are OEM created for direct companies of other goods.

We warmly welcome consumers from other parts of the entire world to check out us. Seeing is believing. We are quite self-confident that following going to our faXiHu (West Lake) Dis.Hu (West Lake) Dis.ty, you will have self-assurance on our items. We have the newest automatic equipments and experienced employees to ensure the secure top quality and massive output. We have the most advanced complex and engineering staff to help most demXiHu (West Lake) Dis.Hu (West Lake) Dis. need on stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd and OEM merchandise.

Looking EPT to assembly you in HangEPT, EPT.

in Maceio Brazil sales price shop near me near me shop factory supplier Smr Metric Series Hollow Shaft Mounted Gearbox Reducer Motor Gearing Speed Reducer manufacturer best Cost Custom Cheap wholesaler

We offer you OEM service. Our company pays certain interest to customers’ demands, listening to the specific specifications of each and every customer and guaranteeing whole fulfillment. we supply one-quit remedy for the buy of mechanical energy transmission items in China.

SMR metric collection hollow shaft mounted EPT EPT motor EPTing velocity EPT

Solution Description

Functions

1. Large toughness of EPT box, EPTs and shafts, strong and durable

two. 2 metric output shaft bore diameters(StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd and Optional)

three. Optional backstop to stop backdriving. Backstop is not suggested for the EPT ratio 5

four. EPT lips skeEPTn oil seal brings together the functions of seal and dust-proof

5. Extensively employed in belt conveyor and pulley EPT method

| SMR Design No. |

Output Shaft Bore [mm] |

Ratio(i) | |

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd | Option | ||

| B | Phi30 | Phi40 | 5:one 13:one 20:1 |

| C | Phi40 | Phi50 | |

| D | Phi50 | Phi55 | |

| E | Phi55 | Phi65 | |

| F | Phi65 | Phi75 | |

| G | Phi75 | Phi85 | |

| H | Phi85 | Phi100 | |

| J | Phi100 | Phi120 | |

Business Details

Certifications

Our Solutions

EPT amp EPT

FAQ

: Are you trading business or producer ?

A: We are manufacturing unit.

Q: How EPT is your supply time?

A: EPTly it is 5-ten daEPTif the merchandise are in stock. or it is 15-20 daEPTif the goods are not in stock, it is in accordance to quantity.

Q: Do you provide samples ? is it cost-free or added ?

A: Indeed, we could supply the sample for totally free cost but do not pay out the EPT of freight.

Q: What is your terms of payment ?

A: Payment lt=1000USD, 100% EPT. Payment gt=1000USD, 30% T/T EPT ,balance before shippment.

If you have one more query, pls truly feel cost-free to make contact with us as beneath:

Contact us

in Sargodha Pakistan sales price shop near me near me shop factory supplier Nmrv110 Speed Reduction Tiller Conveyor Industrial Aluminium Worm Reducer Shaft Mounted Gearbox Motor for Crusher Conveyor manufacturer best Cost Custom Cheap wholesaler

EPG is a professional maker and exporter that is anxious with the style, growth and generation. In addition, all our production processes are in compliance with ISO9002 expectations. Our product variety also handles locking assemblies (clamping factors/locking unit), taper bushes, QD bushes, bolt-on hubs, torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod ends and yokes.

NMRV110 Pace Reduction Tiller Conveyor EPT Aluminium Worm EPT Shaft Mounted EPT EPT For Crusher Conveyor

Our EPT has several items for your picking and we can create as per your drawing or sample to fulfill your EPT ask for

one. Huge output torque

two. Protected, trustworthy, inexpensive and sturdy

three. Steady EPT, peaceful operation

4. High carrying ability

5. Substantial modularization layout, may equip with various outer EPT enter conveniently. Exact same EPT type may possibly equip with different EPT motor. It is effortless to understand the mix and junction amongst every single EPT variety

6. EPT ratio: Fine division, broad scope. The blended EPT sort could form really big EPT ratio, i. E. Output really minimal rotary speed.

seven. Type of set up: The position to be put in is not minimal.

8. Large toughness, compact the box physique of substantial strength cast iron, EPT and EPT shaft adapts the fuel carbonization, quenching and fantastic grinding method, as a result the bearing potential of unit volume is higher.

9. EPT life: UnEPTthe problem of appropriate sort chosen(incXiHu (West Lake) Dis.Hu (West Lake) Dis. deciding on appropriate operation parament ) typical procedure and upkeep, the lifestyle if principal components speed EPT(apart from putting on parts)must not be considerably less than 20000 several hours. The sporting areas incEPT lubricating oil, oil seal and bearing.

10. Minimal sound: Because major parts of pace EPT are processed, and analyzed critically, as a result the sounds of speed EPT is lower.

eleven.Our EPT box have reached the EPT worldwide degree, can replace the identical sort of items EPTed.

HangEPT EPT Market Co., Ltd. is a EPTized supplier of a entire selection of EPTs, sprockets, EPTs, EPT racks, EPT, v belt pulley, timing pulley, V-belts, couplings, EPTd areas and so on.

Owing to our sincerity in giving very best support to our consumers, understXiHu (West Lake) Dis.Hu (West Lake) Dis. of your needs and overriding sense of duty towards filling ordering specifications, we have acquired the EPT of purchasers throughout the world. Getting amassed cherished expertise in cooperating with foreign customers, our items are selling properly in the American, European, South American and Asian markets.Our merchandise are made by modern day computerized EPTry and gear. In the meantime, our items are created in accordance to large quality stXiHu (West Lake) Dis.Hu (West Lake) Dis.rds, and complying with the intercontinental EPT stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd conditions.

With several years’ encounter in this line, we will be EPTed by our benefits in competitive price tag, one particular-time delivery, prompt response, on-hand engineering support and excellent right after-income providers.

Moreover, all our production processes are in compliance with ISO9001 stXiHu (West Lake) Dis.Hu (West Lake) Dis.rds. We also can design and make non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd items to satisfy customers’ EPT specifications. EPT and credit rating are the bases that make a corporation alive. We will provide best solutions and substantial high quality items with all sincerity. If you require any info or samples, please contact us and you will have our soon reply.

Best China manufacturer & factory SMR in Bamako Mali Shaft Mounted worm gear motor reducer With high quality best price

The group has taken part in the creating and revising of ISO/TC100 international chain common numerous years in accomplishment and hosted the 16th ISO/TC100 Intercontinental once-a-year conference in 2004.

Overview

Rapid Specifics

- Applicable Industries:

-

Developing Content Stores, Manufacturing Plant, Machinery Mend Stores

- Gearing Arrangement:

-

Helical

- Output Torque:

-

max 8000NM

- Enter Pace:

-

1440

- Output Velocity:

-

seventy two, 110, 288

- Spot of Origin:Zhejiang, China

- Model Name:

-

OEM

- Product Quantity:

-

SMR

- Rated Electrical power:

-

two.sixty eight~134.2

- color of Shaft Mounted velocity reducer:

-

green blue gray

Offer Capacity

- Offer Potential:

- five hundred Piece/Items for every Month

Packaging & Delivery

- Packaging Details

- standard export packing and wood pallets packing

- Port

- Shanghai or Ningbo

-

Lead Time

: -

Amount(Packing containers) one – 500 >500 Est. Time(times) thirty To be negotiated

Online Customization

Item Description

SMR Shaft Mounted worm equipment motor reducer

one. Precision Higher Good quality Gearing

Computer designed helical gears, powerful alloy components for substantial load ability, ground profile (some intermediate pinions are shaved). Crown tooth profile, in conformance with ISO 1328-1997, 98% performance for per phase, smooth quiet operation with many tooth in mesh.

2. Output Hub

*Regular or substitute output hole diameter for option as adhere to.

|

Merchandise |

Regular output hole diameter |

Different output gap ø |

|

B5 |

ø30 |

ø25/35/forty |

|

B13/twenty |

ø30 |

ø25/35/forty |

|

C5 |

ø40 |

ø35/forty five/50 |

|

C13/20 |

ø40 |

ø35/45/fifty |

|

D5 |

ø50 |

ø45/fifty five/sixty/sixty five |

|

D13/20 |

ø50 |

ø45/fifty five/60/65 |

|

E5 |

ø55 |

ø50/sixty/65 |

|

E13/20 |

ø55 |

ø50/60/65 |

|

F5 |

ø65 |

ø60/70/75 |

|

F13/20 |

ø65 |

ø60/70/75 |

|

G5 |

ø75 |

ø70/80/85 |

|

G13/20 |

ø75 |

ø70/80/85 |

|

H5 |

ø85 |

ø80/ninety/ninety five/a hundred |

|

H13/20 |

ø85 |

ø80/ninety/ninety five/a hundred |

|

J5 |

ø100 |

ø90/ninety five/one hundred and five/a hundred and ten/105120 |

|

J13/20 |

ø100 |

ø90/95/one hundred and five/a hundred and ten/105120 |

3. Strong Alloy Metal Shafts

Sturdy alloy metal, hardened, ground on journals, gear seatings and extensions, for maximum torsional hundreds. Generous size shaft keys for shock loading and conform to ISO requirements.

four, Again Stops

Option elements, anti-operate back again device, are accessible on all thirteen:1 and twenty:1. Ratio units and do not advise for 5:1.

5. Torque Arm Assembly

For straightforward adjustment of the belt.

Detailed Images

Associated Goods

Certifications

Packing & Shipping

Packing Pictures of SMR Shaft Mounted worm gear motor reducer

Inner Packing: PP bag with carton

Outer Packing: Wooden situation

Cargo: 20-thirty days on receiving the deposit.

About Us

About Hangzhou At any time-energy team(HZPT):

Q: Are you buying and selling company or manufacturer ?

A: HZPT team consists in 3 factories and 2 abroad product sales cooperations.we are generating vacuum pumps,air compressors and gearboxes.

Q: How lengthy is your delivery time ? What is your conditions of payment ?

A: Typically it is thirty-forty five times. The time may possibly differ dependent on the item and the level of customization. For regular items,

the paymThe PTO shaft is the mechanical system that transfer the electricity from the tractor to the agricultural employ. The PTO shaft is manufactured of two joints linked by telescopic tubes: a single joint connects the outer tube of the PTO shaft with the tractor electrical power take-off , the other joint connects the inner tube of the PTO shaft with the employ. The variety of the EPG Team PTO shafts involves 9 dimensions of diverse dimensions according to the energy to be transferred . The dimensions of the EPG Team PTO shafts and the electricity that can be transferred at 540 rpm are : Size 1 up to 16HP Dimensions 2 up to 21HP Size 3 up to thirty HP Dimension 4 up to 35HP Size 5 up to 47HP Dimension 6 up to 60HP Dimension 7 up to 70HP Measurement 8 up to 90HP SIZE10 up to 110HPent is: thirty% T/T in advance ,stability before shippment.,for personalized items,50% downpayment is asked for generally.

Q: What is the precise MOQ or cost for your merchandise ?

A: As an OEM company, we can offer and adapt our merchandise to a vast variety of needs.As a result, MOQ and price tag may greatly range with detail dimension, substance and further specificationswhen you area orders,enjoyment contact us in advance to connect all specifics